The application scope of carbonization furnace is very wide, mainly including the following aspects:

Energy industry: Carbonization furnaces can convert coal into lignite or anthracite, which can be used as fuel for power plants or raw materials for thermal power plants.

Chemical industry: Carbonized coke can be used as a catalyst carrier, reducing agent, or raw material for the production of certain chemicals in chemical processes.

In the field of environmental protection, biomass carbonization can be used as organic fertilizer to improve soil fertility and environmental quality; It can also be used as a material for adsorbing harmful substances in the sewage treatment process.

Agriculture: Processing crop residues (such as rice husks and corn husks) for biological carbonization, for composting or production of biogas, etc.

Wood processing industry: Preheating and carbonization treatment of wood can improve its insect resistance and durability, reduce smoke and harmful gas emissions during combustion.

Food and beverages: In some cases, such as the residue after wine fermentation, it can be processed through a carbonization furnace to extract useful ingredients.

Scientific research: used in the laboratory to study the pyrolysis reaction of organic matter or the preparation of biochar.

Special material manufacturing: Carbonization process is also used in the manufacturing of batteries, fuel cells, and catalytic materials.

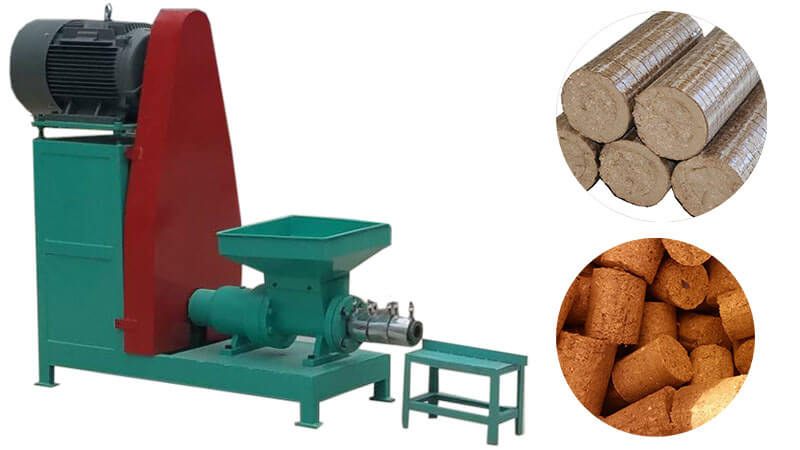

In addition, the carbonization furnace can also process various materials, including carbon containing wood materials (such as sawdust, rice husks, peanut shells, plant straw, bark, etc.), waste plastics, oil sludge and oily waste, electronic waste, etc. These materials undergo high-temperature dry distillation and anaerobic carbonization treatment in the carbonization furnace, which can generate useful carbonization products or be used as fuel.

WeChat / WhatsApp

WeChat / WhatsApp

Online messageIf you have any questions, please leave a message here to tell us, we will contact you in time!

Online messageIf you have any questions, please leave a message here to tell us, we will contact you in time! Products

Products

Online service

Online service Telephone

Telephone Message

Message