The maintenance and upkeep of carbonization furnaces require attention to daily inspections, regular cleaning, and equipment maintenance to ensure production efficiency and safety. The following are specific points to consider:

Routine inspection and maintenance

Wearing parts inspection: Before operation, inspect the condition of wearing parts such as bearings and gears, and replace them promptly if any damage is found

Operational guidelines: Strictly adhere to operational procedures, and refrain from unauthorized modifications to equipment structure or process flow

Sealing maintenance: Ensure good sealing at the feed inlet to prevent air leakage during the carbonization process, which can lead to incomplete carbonization

Regular cleaning and maintenance

Internal cleaning: Clean the residues inside the furnace every 7 days or so to prevent pipeline blockage

External maintenance: Clean the carbon ash after use, keep the equipment dry and ventilated, and avoid moisture-prone environments that can cause rusting of components

Maintenance of key components

Fan maintenance: Check whether the fan operates smoothly and regularly clean the dust accumulated in the air duct

Flue gas purification system: Ensure the normal operation of the flue gas purification device, recover combustible gases, and reduce environmental pollution

precautions

If any abnormalities are detected, immediately shut down the machine for maintenance to avoid operating with defects, which could lead to more serious malfunctions

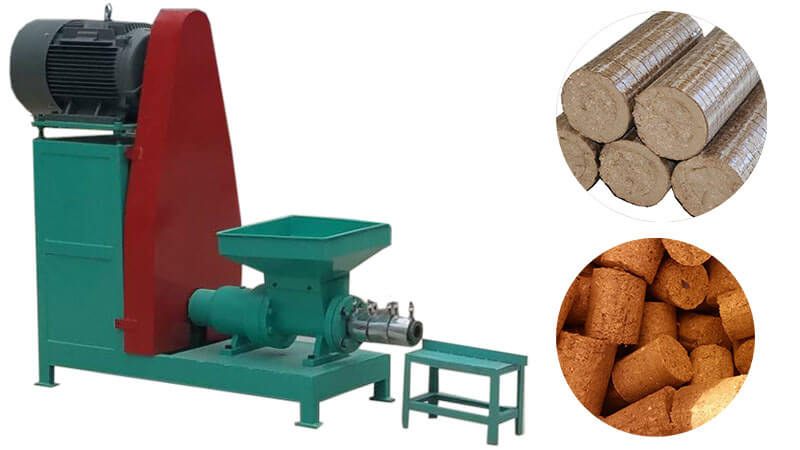

The raw materials need to be crushed in advance to the specified particle size (such as not exceeding 2 centimeters), and the moisture content should be controlled within a reasonable range (it is recommended to be ≤25%)

WeChat / WhatsApp

WeChat / WhatsApp

Online messageIf you have any questions, please leave a message here to tell us, we will contact you in time!

Online messageIf you have any questions, please leave a message here to tell us, we will contact you in time! Products

Products

Online service

Online service Telephone

Telephone Message

Message