The vertical packing machine achieves a significant reduction in material volume through high-pressure compression and has the following significant advantages:

Space utilization efficiency improvement

After compression, the volume of the material is usually reduced to 1/3 to 1/5 of its original size, effectively reducing storage space occupation. For example, compressed waste paper recycling can increase the transportation volume of a single vehicle by more than three times, significantly reducing logistics costs.

Optimization of transportation efficiency

Compressed materials are more compact, reducing transportation frequency and carbon emissions. After a certain waste paper recycling enterprise used a 150 ton vertical baler, the monthly transportation cost decreased by 24000 yuan and the site utilization rate increased by 40%.

Environmental protection and energy-saving characteristics

The enclosed design reduces dust pollution and complies with atmospheric pollutant emission standards. The new servo hydraulic system is 40% more energy-efficient than traditional motors and consumes only 1.2 kWh of electricity per package.

automated operation

The high-end models are equipped with PLC control system and automatic bundling device, which can detect the filling amount in real time and optimize the compression effect. For example, AI visual recognition systems can automatically adjust compression parameters to reduce manual intervention.

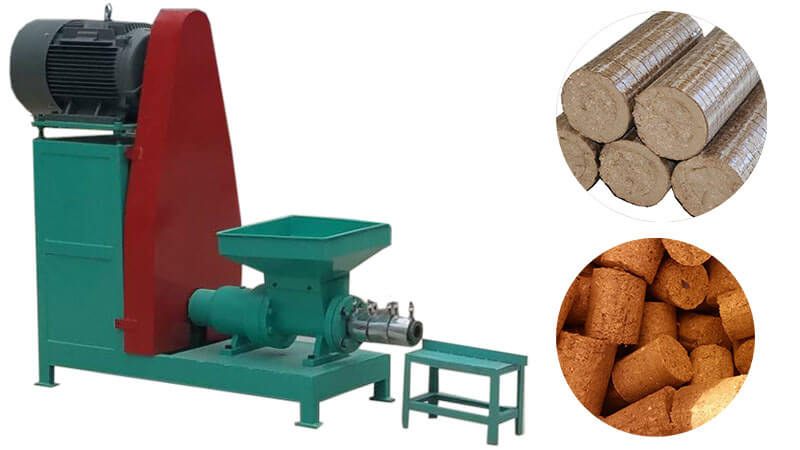

Widely applicable scenarios

Suitable for processing various materials such as waste paper, plastic, metal waste, textile scraps, etc. In steel plant production lines, vertical packaging machines can reduce packaging material waste, improve production efficiency, and reduce operating costs.

WeChat / WhatsApp

WeChat / WhatsApp

Online messageIf you have any questions, please leave a message here to tell us, we will contact you in time!

Online messageIf you have any questions, please leave a message here to tell us, we will contact you in time! Products

Products

Online service

Online service Telephone

Telephone Message

Message