Temperature control in a horizontal carbonization furnace is crucial for ensuring the efficient conversion of biomass raw materials into high-quality charcoal.

It typically involves phased temperature management to accommodate the demands of different chemical reactions.

Temperature control must be carried out in stages: The carbonization process generally consists of three stages:

1. Drying stage: Temperature is controlled between 0°C and 160°C. The main purpose is to evaporate moisture from the raw materials.

The chemical composition of the raw materials remains largely unchanged during this stage.

2. Pyrolysis stage: Temperature ranges from 160°C to 280°C. The woody material begins to thermally decompose, producing volatile substances such as carbon dioxide, carbon monoxide, and wood vinegar.

3. Full carbonization stage: Temperature rises to 300°C to 650°C. The material undergoes rapid thermal decomposition, generating large amounts of combustible gases (such as methane and ethylene).

The combustion of these gases provides heat, promoting continued carbonization. For high-quality charcoal, the temperature is often controlled between 500°C and 600°C to optimize the carbon structure and energy density.

Temperature control has a significant impact on carbonization results: Precise temperature management directly affects carbonization efficiency, product quality, and environmental friendliness.

Within the 500°C to 600°C range, biomass volatiles are fully released, and the carbon structure is effectively preserved, resulting in charcoal with high calorific value, long burning time, and good stability.

Temperatures that are too low (e.g., below 600°C) may lead to incomplete carbonization and a lower calorific value (approximately 5000~6000 kcal/kg), while reaching 700°C can increase the calorific value to 7000~7500 kcal/kg.

Furthermore, precise temperature control can reduce harmful gas emissions, achieve energy self-sufficiency through the recycling and combustion of combustible gases, and reduce pollution.

Key points to note during actual operation:

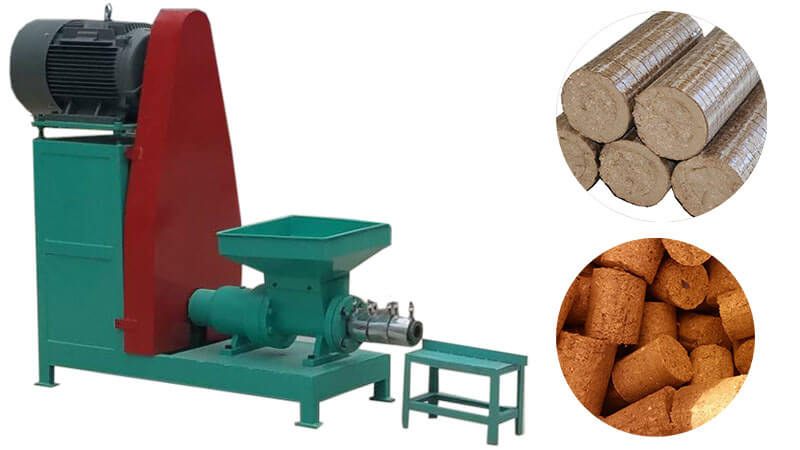

The heating rate must be adjusted according to the characteristics of the raw materials (such as machine-made briquettes or logs) to avoid excessively rapid heating that could lead to cracking or uneven carbonization.

The equipment is typically equipped with a temperature controller and a flue gas purification system to maintain a stable temperature by adjusting the feed, dehumidification, and gas circulation.

For example, during the full carbonization stage, it is essential to ensure that the combustible gas is fully burned to mark the completion of carbonization.

Simultaneously, avoid sudden pressure changes inside the furnace; wait until the temperature drops to approximately 50°C before starting the furnace to prevent open flames and safety hazards.

WeChat / WhatsApp

WeChat / WhatsApp

Online messageIf you have any questions, please leave a message here to tell us, we will contact you in time!

Online messageIf you have any questions, please leave a message here to tell us, we will contact you in time! Products

Products

Online service

Online service Telephone

Telephone Message

Message