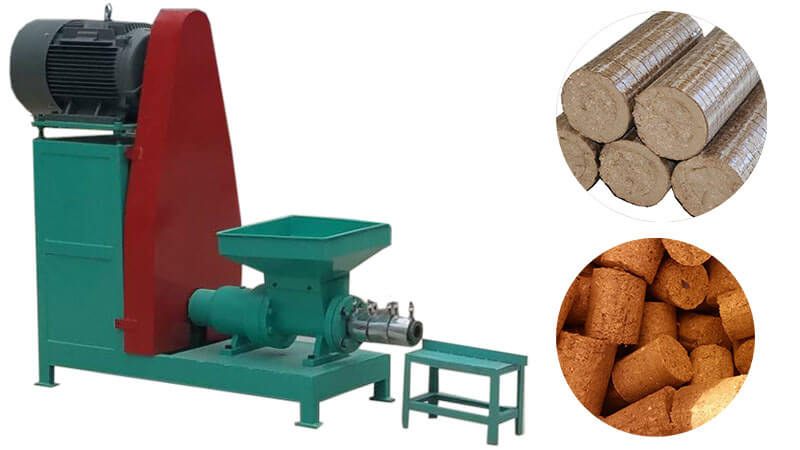

An airflow dryer is an industrial device that uses high-temperature airflow to rapidly dry materials.

Its applications are wide-ranging, primarily depending on the material's physical form, moisture content, and properties.

This equipment is suitable for drying powdery, granular, flaky, and heat-sensitive materials,

especially those with high moisture content, such as powdery or granular materials with a moisture content between 10% and 40%.

Typical applications include drying starch, rice flour, food additives, pharmaceutical intermediates, chemical raw materials (such as calcium carbonate and copper sulfate), animal feed (such as fishmeal and distiller's grains),

mining materials (such as coal powder and mineral powder), and sludge.

For paste-like or viscous materials, some specially designed airflow dryers (such as the JG series and QF series) can also handle them, such as precipitated silica, catalysts, and sludge—materials that are difficult to dry.

In industry applications, airflow dryers cover the food, pharmaceutical, chemical, animal feed, mining, papermaking, and environmental protection sectors.

For example, it is used in the food industry for drying starch and additives, in the pharmaceutical industry for processing heat-sensitive drugs, and in the chemical industry for dehydrating resins and pigments.

It should be noted that airflow dryers have certain requirements regarding the form of the material.

They are not suitable for materials that are extremely prone to sticking to the walls, are very viscous, or need to be dried to below the critical moisture content.

Additionally, because the drying process may generate dust, caution must be exercised when handling flammable or perishable materials.

WeChat / WhatsApp

WeChat / WhatsApp

Online messageIf you have any questions, please leave a message here to tell us, we will contact you in time!

Online messageIf you have any questions, please leave a message here to tell us, we will contact you in time! Products

Products

Online service

Online service Telephone

Telephone Message

Message