The operation of an airflow dryer varies depending on the specific type (e.g., industrial material drying or laboratory glassware drying). The following guidance is based on common operating procedures.

Pre-operation preparation: Check that the equipment is securely installed, ensure a safe power connection (usually 220V AC), and check the air system for leaks.

For industrial airflow dryers, confirm that the pre-filter's automatic drain valve is functioning correctly, the system pressure is balanced, and clean any debris from the feed inlet.

For laboratory glass airflow dryers, select the appropriate duct size based on the instrument size.

Start-up and heating: After connecting the power, first turn on the fan to check the rotation direction and the suction at the feed inlet.

Then set the temperature parameters (e.g., using the temperature knob to set the desired range).

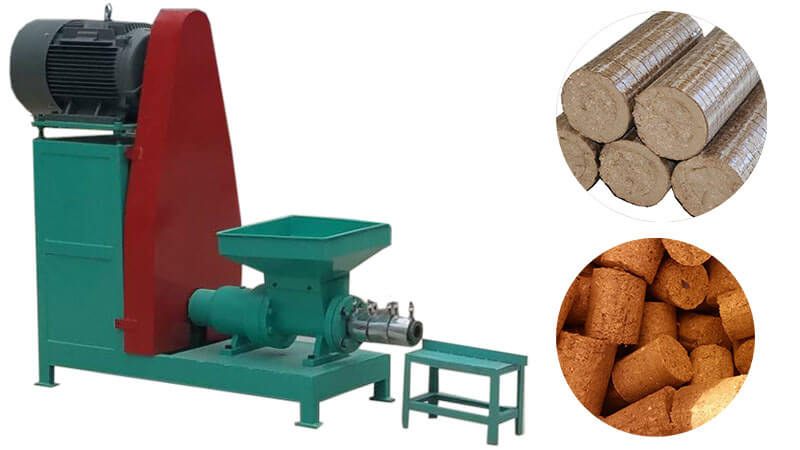

During heating, the hot air indicator light will automatically start and stop according to temperature fluctuations. Feeding and Drying Process: For industrial equipment,

the material should be evenly added to the lower part of the drying tube.

It is instantly dispersed and fluidized by a high-speed hot airflow, and the material dries rapidly in the gas-solid mixture (residence time is typically 1-4 seconds).

During operation, the feeder speed needs to be adjusted according to the gas outlet temperature to maintain stability.

For laboratory equipment, the drying instrument should be inverted and inserted into the support, with the test tube opening facing downwards.

Hot air is used to dry the material from the inner wall. The drying time is adjusted according to the size of the instrument (e.g., approximately 5-10 minutes for a three-necked flask).

Monitoring and Adjustment: During the drying process, the system pressure, temperature, and material flow status need to be continuously monitored.

For industrial equipment, attention should be paid to safety devices such as explosion relief valves; any abnormalities should be addressed promptly.

For laboratory equipment, overheating should be avoided; ensure the instrument has cooled down before use. Shutdown and Maintenance: After drying is complete, first turn off the hot air switch.

After the instrument has cooled down or the material in the system has been emptied, disconnect the power.

Regularly clean the slag discharge port, check the bag filter and pipeline cleanliness to prevent blockages.

WeChat / WhatsApp

WeChat / WhatsApp

Online messageIf you have any questions, please leave a message here to tell us, we will contact you in time!

Online messageIf you have any questions, please leave a message here to tell us, we will contact you in time! Products

Products

Online service

Online service Telephone

Telephone Message

Message